Electric Motor Retention Sleeves

High speed capable rotors

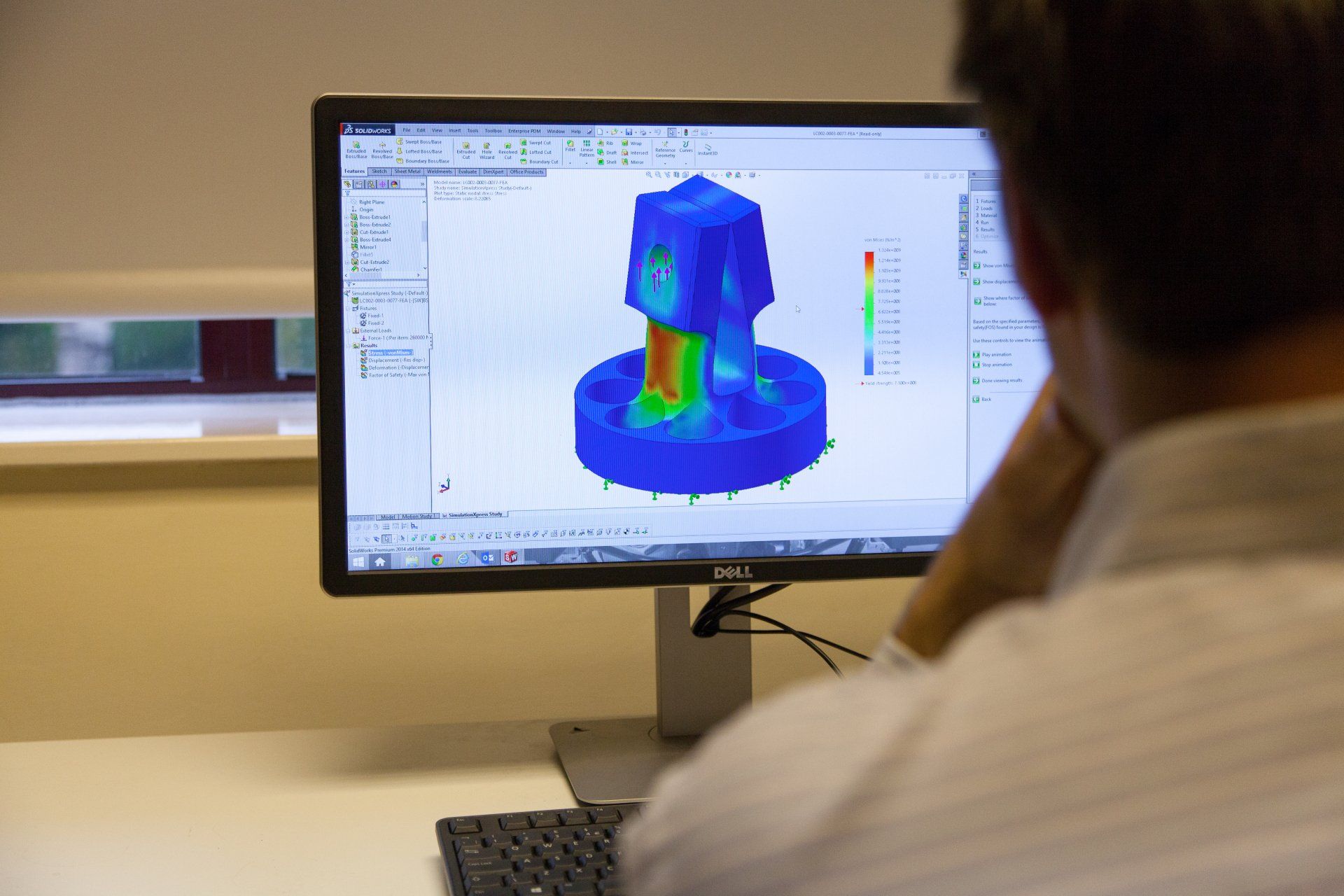

As we move towards the electric future, high speed rotors will become a key component of the electrification supply chain. The rotors required to power electric vehicles rotate at very high speed. The centripetal forces generated by rotating at these high speeds need to be contained with retention sleeves. Lentus can design the sleeves to meet the specific requirements of each application and design the assembly process to enable high performance rotors to be delivered.

Composite retention sleeves

Over the last two to three years Lentus have been developing composite retention sleeves and pressing capability for use in electric rotor applications and have been working to industrialise the process. Lentus have recently won contracts to supply thousands of rotor sleeves each year on an ongoing basis. The composites sleeves, manufactured in a humidity and temperature-controlled environment on our CNC winding machines, can be pressed onto rotor assemblies and work to retain the magnets in the rotor at the highest speeds.

Precision machining of composites

Lentus design specific laminates for specific applications to match the expansion of the rotor itself (matching both thermal and rotational expansion) and prevent collision/ clash conditions during rotor function. Each composite sleeve is precision machined on our CNC lathe to a specific length and the ID and OD of the sleeves are controlled to the tune of microns by the wind tooling.

Our composite expertise and novel manufacture and inspection techniques make us very competitive on price and allow us to manufacture components at volume without the requirement for large upfront investment.

"As we move towards the electric future, high speed rotors will become a key component of the electrification supply chain."

Find out more about complementary products and services

Lentus Composites, together with SST Technology provide an array of products and services; blending engineering disciplines and techniques to meet our client’s needs.